Building components manufacturer

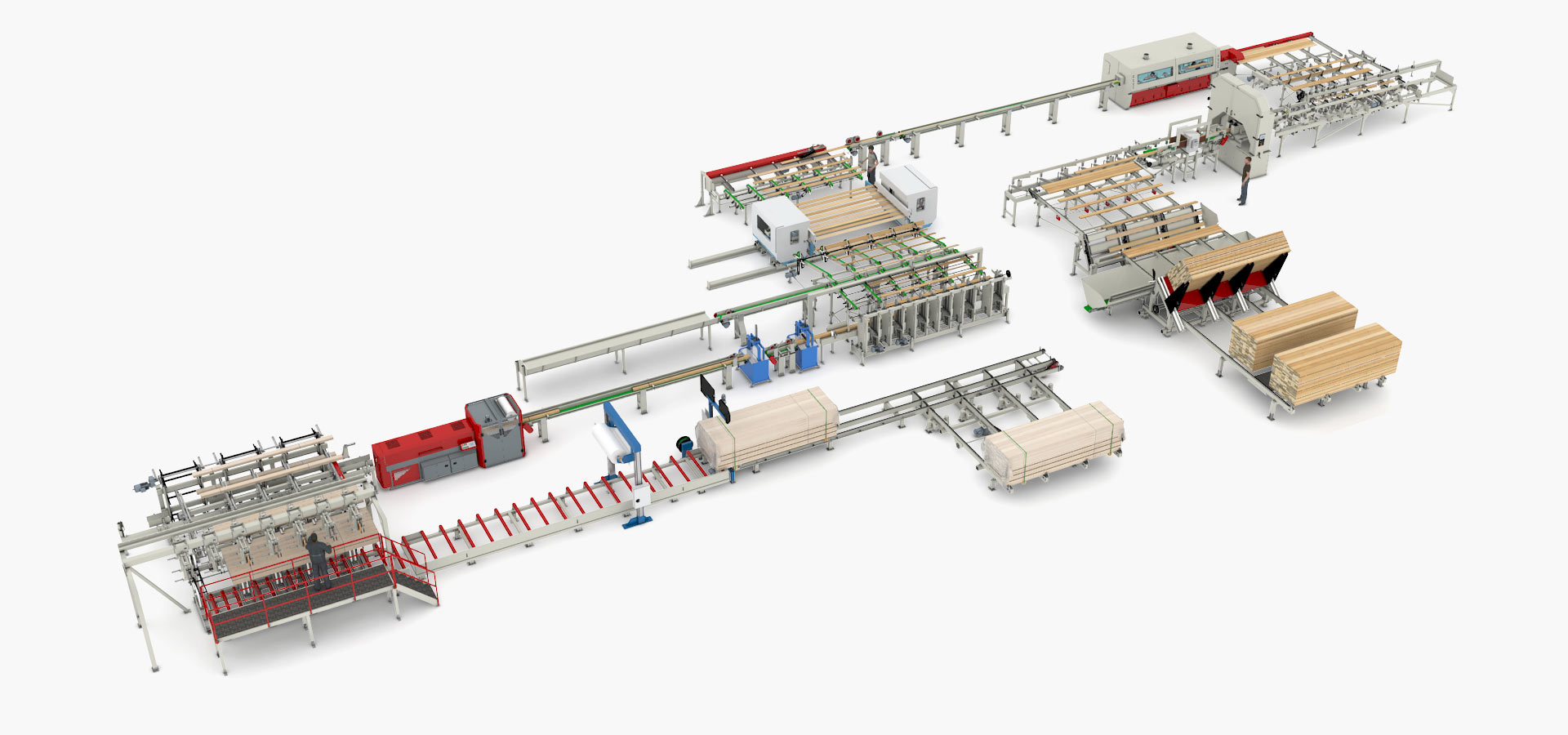

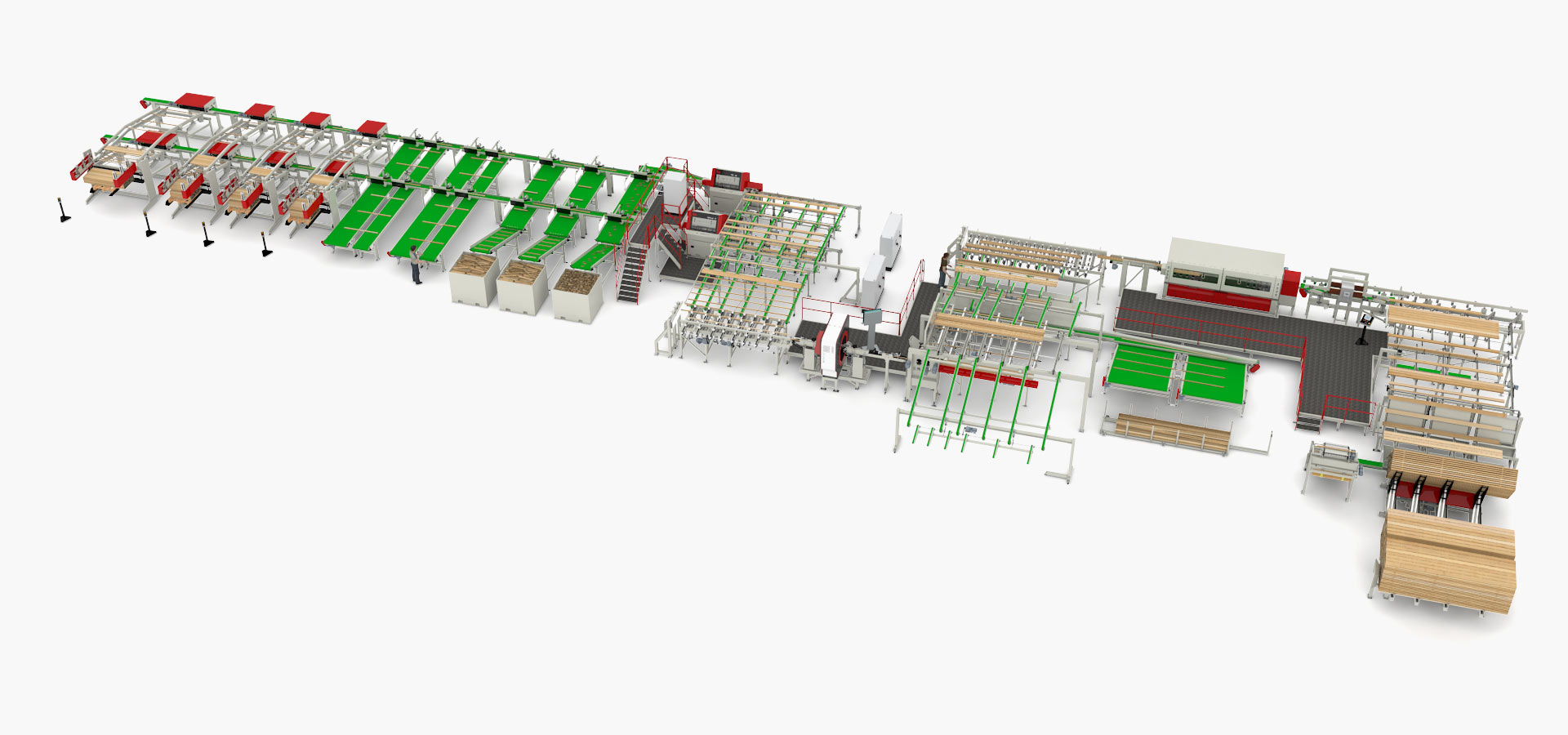

The customized system solutions are individually designed and manufactured, always considering the customer’s production and main machines.This gives our customers a highly integrated line that is fully optimized regarding facilities, production, capacities, yield, and staff resources.

Building components manufacturer

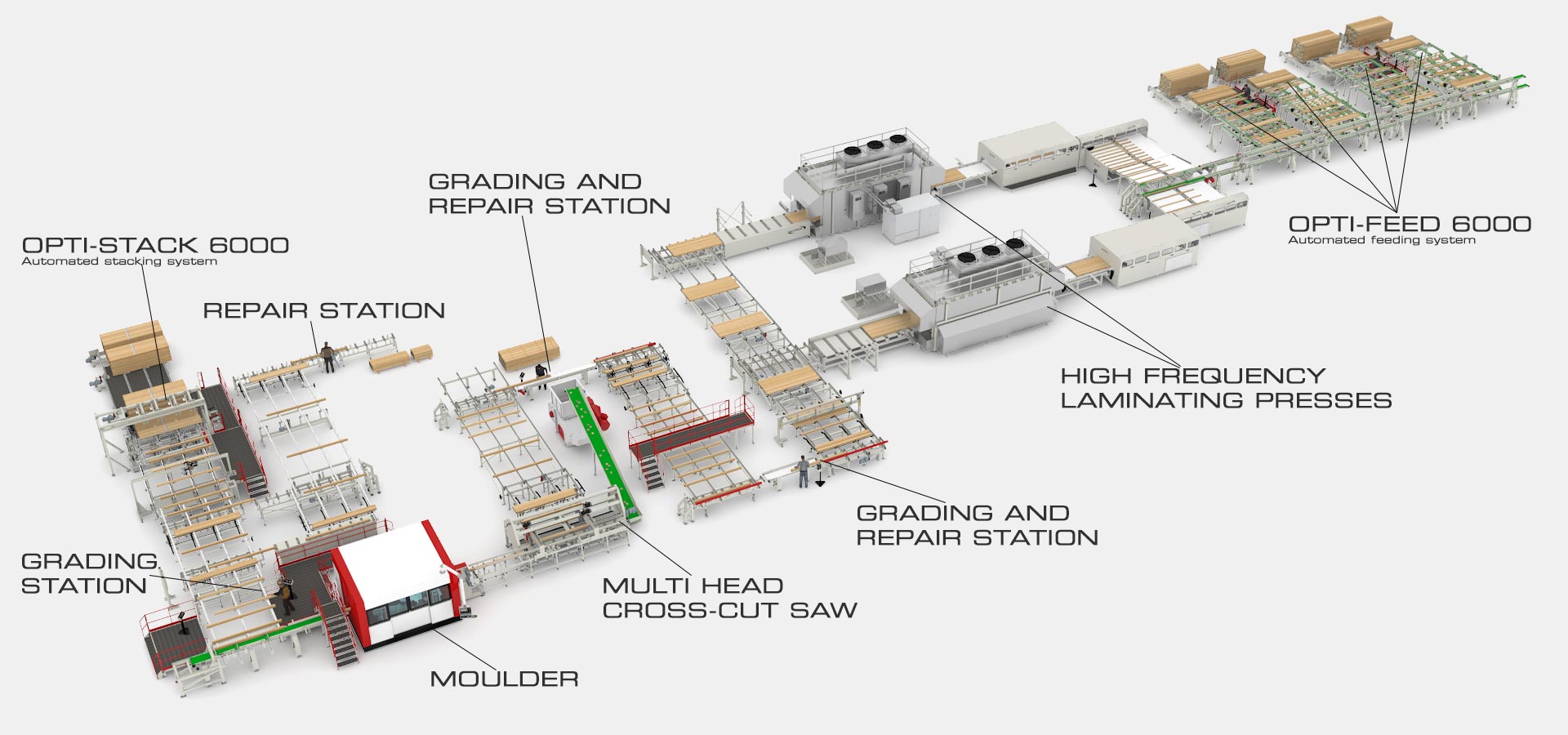

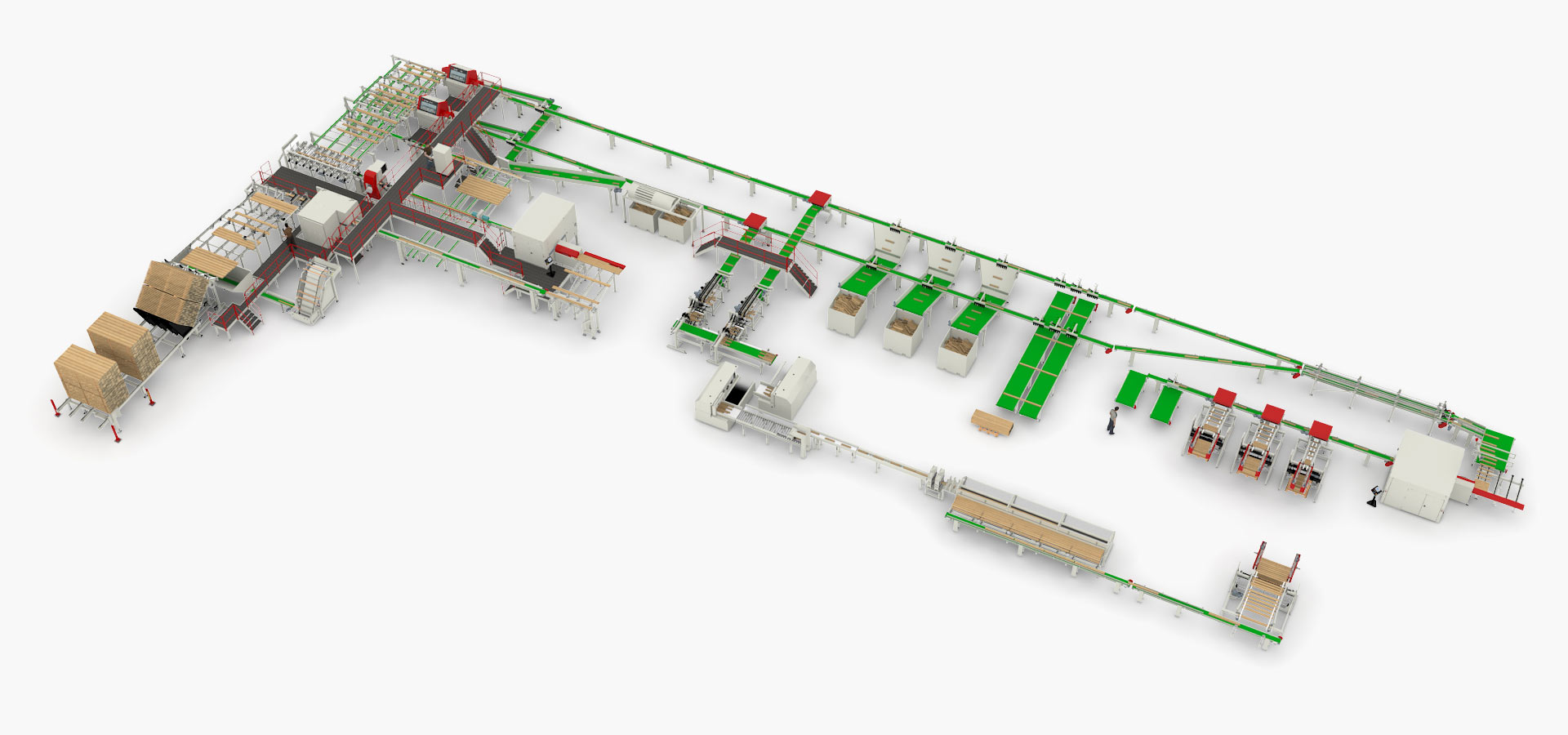

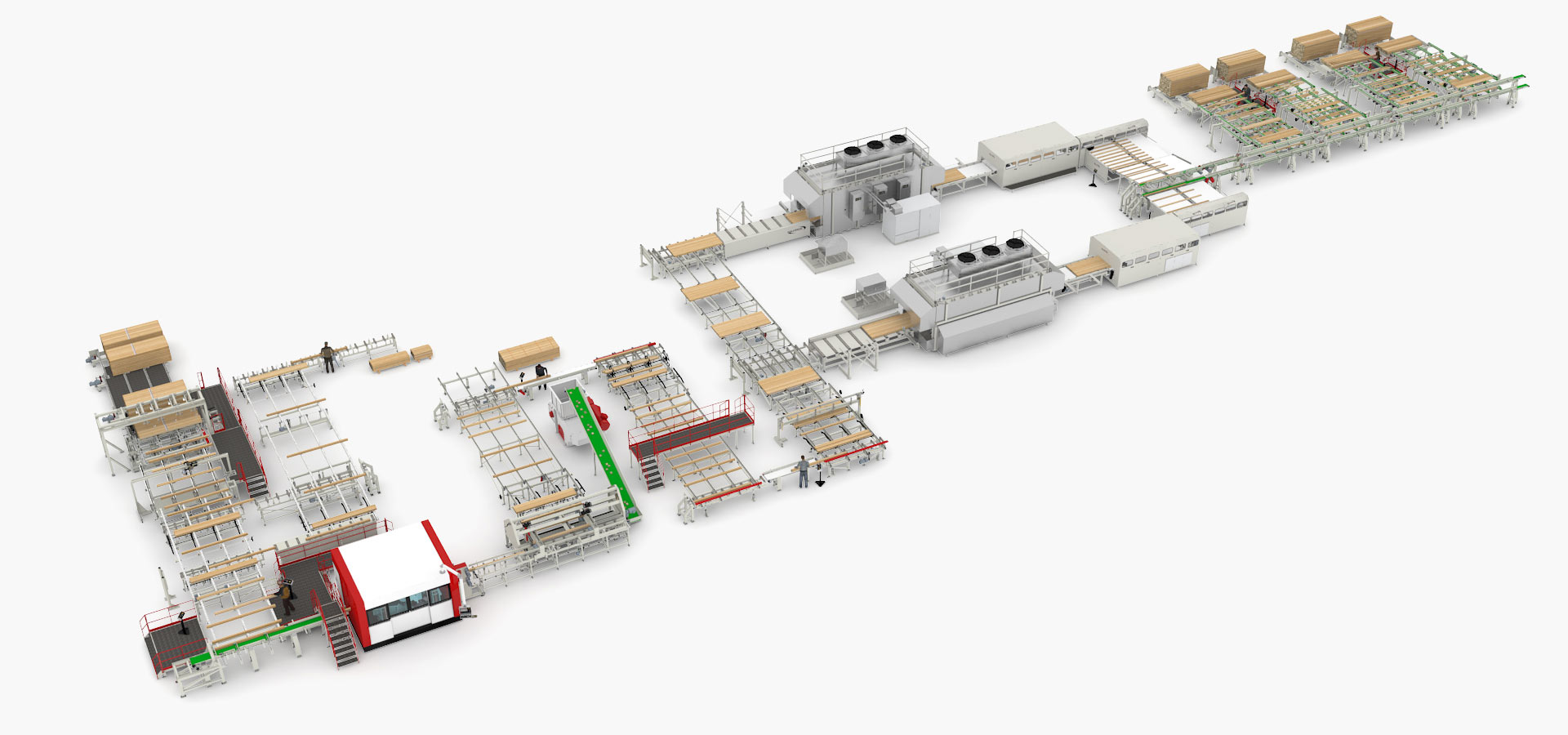

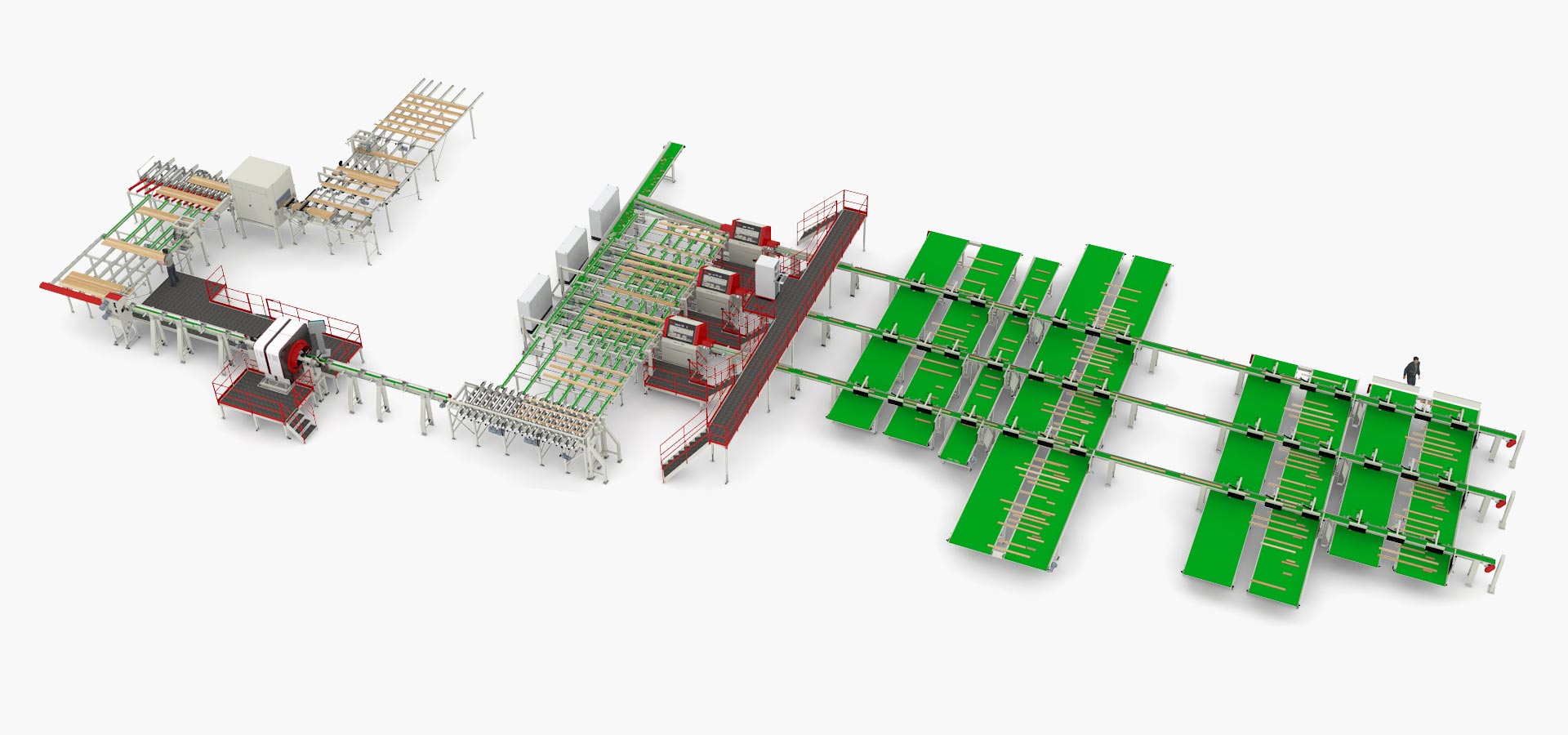

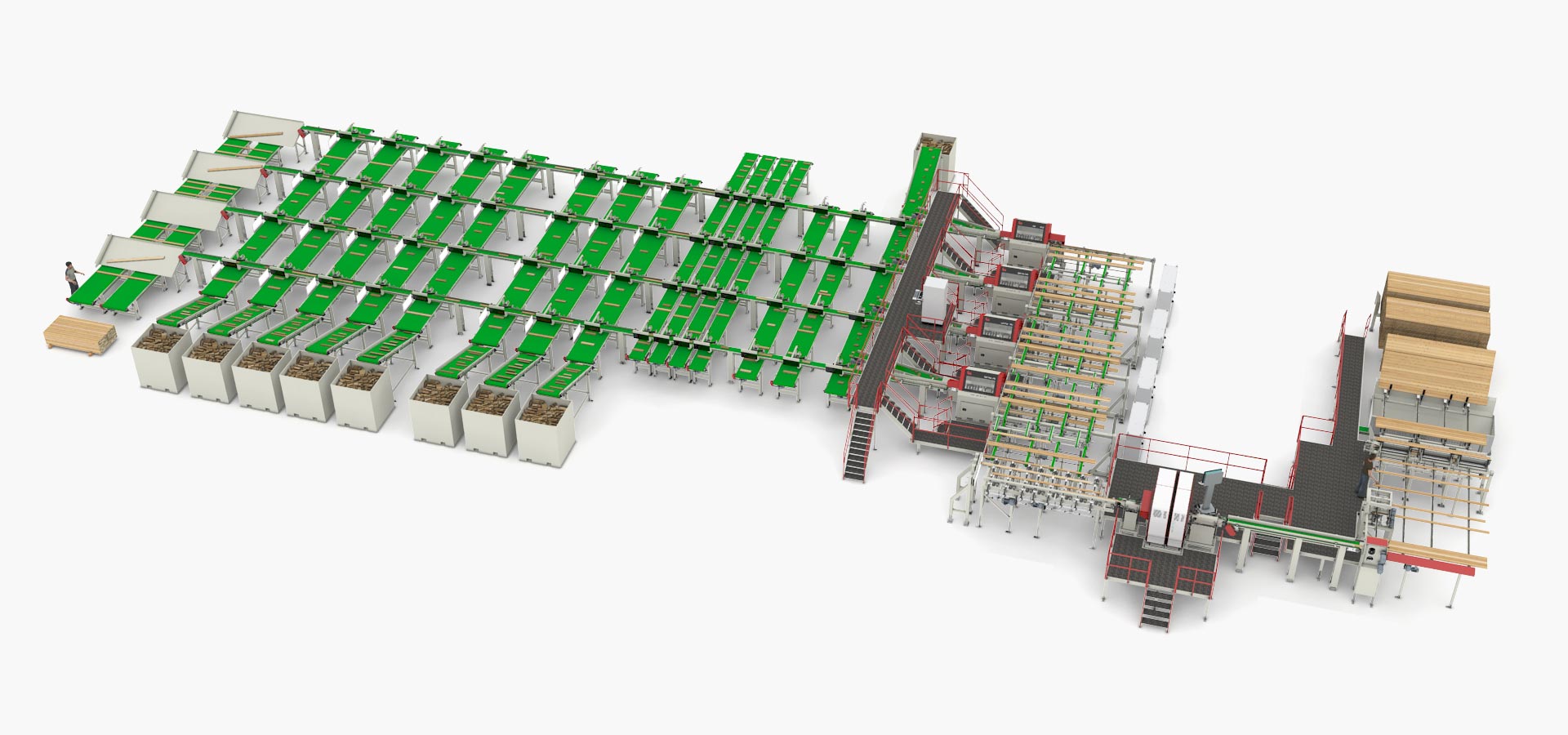

This Opti-Solution is a material handling system that consists of four feeding systems, model Opti-Feed 6000, feeding four different qualities to two high frequency laminating presses.

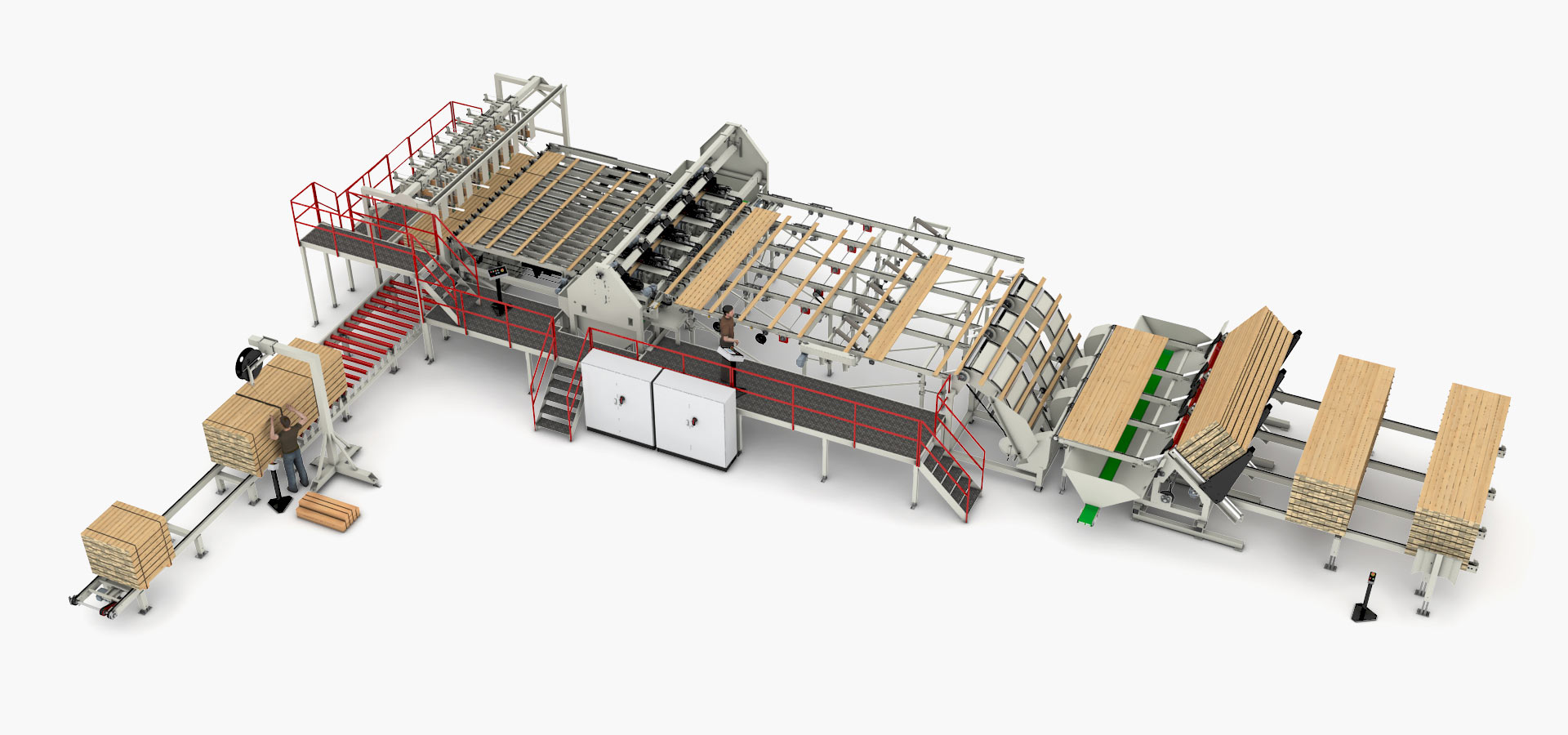

After laminating, the beams are separated in a buffer system and automatically transported to two grading and repair stations. If needed, the beams are repaired manually by two operators. After the grading and repair stations the beams are transported through a multi head cross-cut saw, model MK2 where the ends are trimmed before moulding.

After the moulder the beams are once again quality checked and repaired if needed, then labelled and transported to the automated stacking machine, model Opti-Stack 6000.

System TM’s lines are characterized by:

- System TM’s optimizing software – the only software available optimizing on both wood resources and the overall line capacity.

- System TM’s individual design. The lines are individually designed and manufactured, always considering the customer’s production and main machines. This ensures our customers high-performance materials handling, and 100% workpiece control throughout the line.

- Complete hard- and software integration between all functions of the line.

- The best return on investment.

- Low labor costs and optimal utilization of the wood, ensure our customers to stay competitive in the global market.

- Higher efficiency for all main machines.

- Automatic production changeover from one central computer.